industries commonly use honeycomb panels

In the building industry, honeycomb panels are used for the cladding of buildings and for walls. They are lightweight and provide a high stiffness-to-weight ratio. They are also thermally and acoustically insulated. They are also used as working surfaces for automatic machines and for laser jet cutting. They are a suitable alternative to solid aluminium, wood or MDF because of their excellent rigidity and low weight.

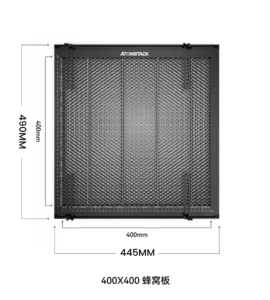

The shape of the honeycomb cells is often varied to meet different engineering requirements. The most common shapes are hexagonal and triangular, but circular-cored square and rectangular cells are also used. The cell size and density depends on the engineering application, but the general principle is that they form complex compound curved composite structures. This enables the face layers to withstand shear loads, without the need for excessive mechanical force or heating.

honecomb panel atomstack can be used for a wide variety of applications, from the construction of airplane wings and train bulkheads to the design of car interiors and doors. Stainless steel honeycomb panels are a good choice for the aerospace industry because of their excellent corrosion resistance. They are also a good option for transportation and logistics industries because of their durability and light weight.

What types of industries commonly use honeycomb panels?

Aside from being used in building cladding, honeycomb panels are also incorporated into mobile homes and other extra structures that serve as temporary or portable buildings for schools, churches, and other organizations. They can also be found in commercial vehicles, buses, and ships. Moreover, the lightweight nature of honeycomb panels makes them an ideal choice for a range of other applications in many industries.

The growth of the global honeycomb core materials market is largely driven by increasing consumption in the automotive industry. This is mainly because the honeycomb structure of these materials allows for a lighter and more energy-efficient vehicle. These materials are also used to make car spoilers, floors, chassis components, diffusers, and crash-absorbers.

There are two types of facing sheets that are typically used with the honeycomb core: thermoset FRP sheets and thermoplastic CFRT sheet. While the former is bonded with the core using adhesives, the latter is bonded to the core using a thermal bonding process.

The covid-19 pandemic affected the global economy and several end-use industries including the automotive, aerospace, construction, and aviation industries. The outbreak also impacted the availability of raw material for the production of these products. Nonetheless, the recovery of these industries is expected to drive the demand for honeycomb panels. Hence, the market for this product is likely to grow at a steady pace in 2023. In terms of the regional share, North America is the leading market for honeycomb panels due to its growing aerospace and transportation industry. Additionally, the region is also a major manufacturing hub for automobiles.