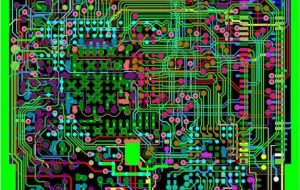

RF Circuit Board Design

RF circuit boards are essential to high-powered applications, such as cell phones and wireless communication devices. The specialized boards must be designed with a number of key considerations, including power distribution, signal integrity, and electromagnetic compatibility (EMI) and noise reduction. RF PCBs are often built using rigid substrate materials like polyimide or liquid crystal polymer to increase component density and allow for more efficient signal transmission. These board designs are also typically created using techniques like laser drilling to make microvias that allow for high-frequency signal routing.

In RF circuits, signal quality is highly dependent on power integrity. Accurate power routing helps minimize voltage dips, decrease power losses, and prevent noise coupling into vulnerable RF components. To help mitigate these issues, RF designers should use wide, low-impedance power traces and employ impedance-matching to ensure that the RF circuit’s characteristic impedance is matched at both the load and source. Additionally, RF circuits should include decoupling capacitors to remove noise from the power supply.

High-power RF components generate a large amount of heat. To avoid hot spots and a large increase in temperature, engineers should place these components near the center of the board to enable more uniform heat diffusion throughout the board. They should also incorporate large copper planes and vias to transfer heat away from the rf circuit board to the surrounding environment.

RF Circuit Board Design for High-Power Applications

Proper grounding is another important aspect of RF circuits, as it provides a low-impedance return path for RF signals and reduces interference or noise. For optimum performance, a dedicated ground plane should be placed under each RF layer. In addition, each RF trace should have a grounding via for every shunt component connected to the trace. Finally, it is critical to minimize parasitic capacitance between the grounding wire and a test point. To do so, engineers should use gradual curved bends instead of sharp right turns, which are more effective for a trace’s performance.

To reduce flicker noise in RF circuits, designers must carefully consider the board’s design and layout. This can be done by minimizing the number of layers, ensuring that the RF layer is immediately followed by a ground plane, and avoiding the placement of any non-RF components on the same layer as an RF trace.

RF circuits are very sensitive to electromagnetic interference and other types of noise. To prevent these issues, engineers should consider the board’s material selection, dielectric constant, loss tangent, and coefficient of thermal expansion (CTE) values, as well as the RF trace width, length, and shape. In addition, they should address EMI and EMC concerns by using EMI shielding and filters as necessary. Lastly, they should use simulation tools to evaluate their circuit board’s design before creating a prototype to ensure that it will function as intended. Getting these details right from the start can save time and money in the long run. In addition, it can help avoid costly mistakes that could delay project completion. By following these tips, engineers can create a robust and efficient RF circuit board.